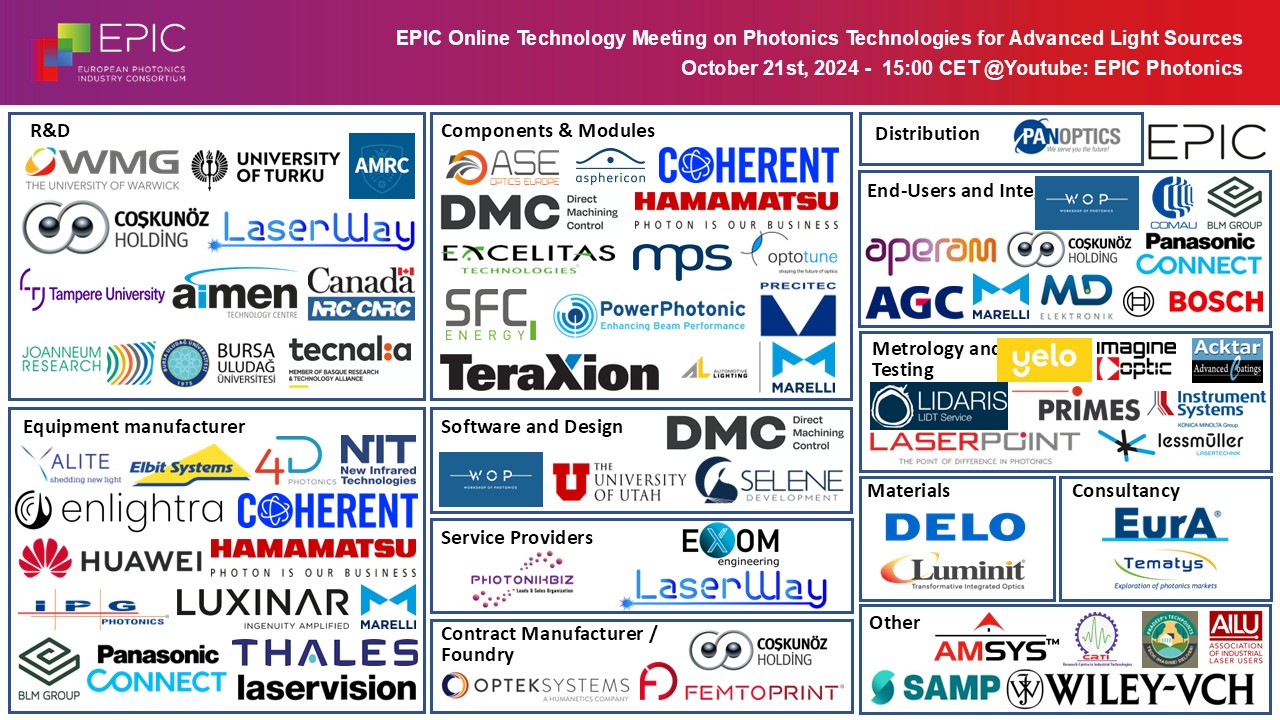

Laser technology has established itself as one of the best processing tools for improving manufacturing flexibility and product reliability in the automotive industry. Laser cutting and welding reached a high level of maturity, and they are already implemented in production lines. Other laser processes, as texturing, structuring or ablation are also emerging with a high potential to improve the efficiency of the process and the quality of the final product. Moreover, the increasing demand for modern electric vehicles has led to the need for more efficient batteries with enhanced performances. The different innovative designs and constructions require new production concepts and laser processes has solved different drawbacks of other production alternatives in applications such as cutting of separators and electrodes or welding of dissimilar metals.

We will cover in this meeting the latest developments and the trends in this market and will discuss the upcoming needs and challenges from the end users regarding new tools and components.