Laser Applications Boost Battery Manufacturing Efficiency

The battery market will have a significant impact in Europe in the coming years, and photonics, in particular lasers and sensors, is set to play a major role. The manufacturing of batteries for electric vehicles necessitates a shift from traditional factories to the establishment of gigafactories – large manufacturing facilities dedicated to the production of components and products related to electrification and decarbonization technologies. Laser cutting and welding techniques have already been seamlessly integrated into battery production lines, reducing time and costs while increasing productivity.

Download the press release. The growing demand for modern electric vehicles has necessitated the development of more efficient batteries with enhanced performance. Laser cutting and welding techniques are already integrated into battery production lines. Laser cutting finds applications in various battery components, including separators and electrodes. Laser welding has evolved to meet the requirements of minimal heat-affected zones, precise control of penetration depth, high processing speed, and the welding of dissimilar metals, thanks to the development of new laser sources with the right parameters. During this two-day meeting hosted by the University of Stuttgart at the cutting-edge research campus ARENA2036, a panel of experts discussed the latest developments, new applications, and market trends. Take a look at the album of pictures of the event.

In the domain of Cathode/Anode Manufacturing, Precitec’s sensors allow the inline and contactless measurement of critical quality criteria in cell production. Meanwhile, TRUMPF highlighted the challenges of Laser Cutting of Battery Foils due to the complexity of foil materials and electrode designs.

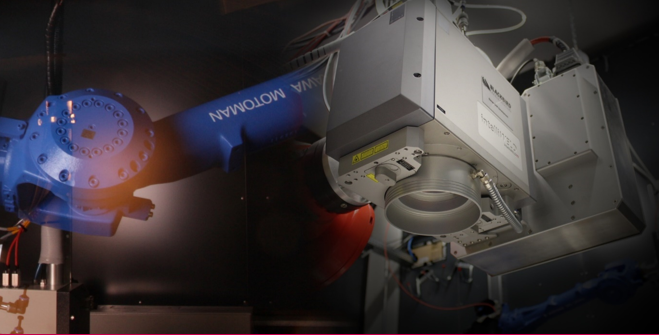

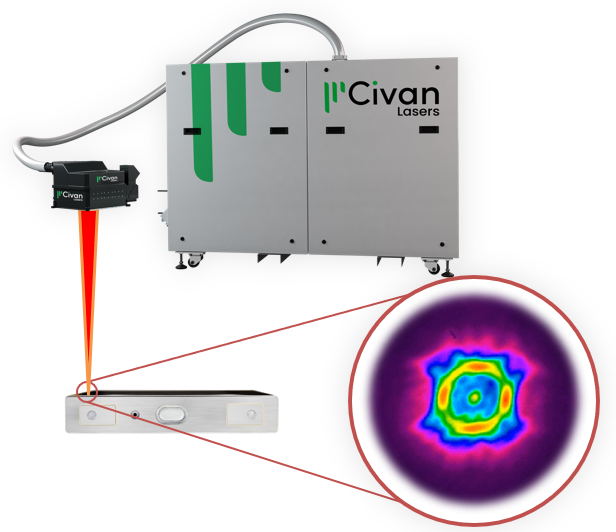

In the context of Battery Cell Manufacturing, Ennovasense introduced its single-sided sensor for measuring the thickness of various types and geometries of coatings on bipolar plates. The lightweight and thermally conductive nature of aluminum makes it advantageous for e-mobility applications, and Civan Lasers has developed dynamic laser beam welding for high-strength aluminum battery housings. An improved cycle time is essential for the electric vehicle business model. Which is why Scanlab developed on-the-fly welding for 1D linear stages to enhance battery manufacturing efficiency.

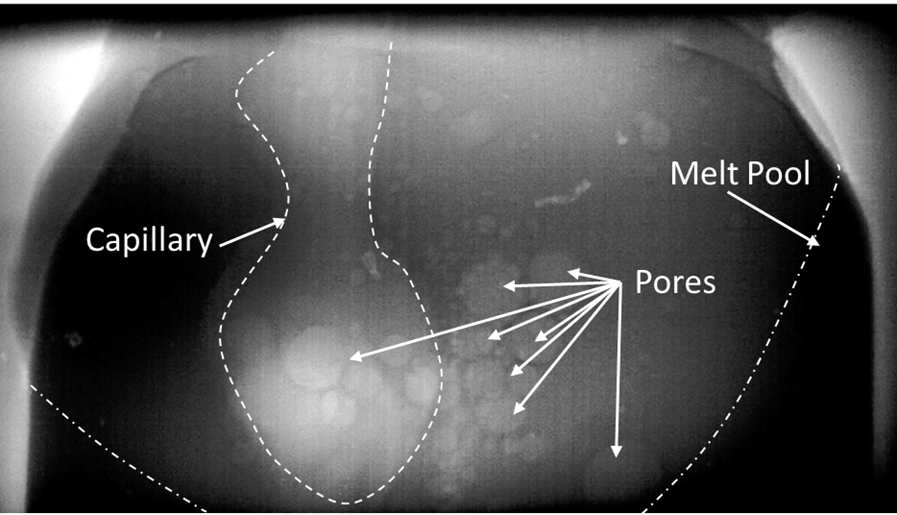

Photonics applications in Battery Module Manufacturing not only reduce time and costs but also enhance productivity, as PRIMES mentioned during their presentation. While in the field of Fuel Cell Manufacturing, the Institut für Strahlwerkzeuge has developed a High-speed X-Ray Imaging that detects the formation of pores during Welding of Copper Pins.

The EPIC Meeting on Laser Applications along Battery Manufacturing Process at ARENA2036 has featured 20 speakers representing the entire supply chain, including automotive companies, battery manufacturers, process monitoring firms, and laser manufacturers. For the complete agenda, please click here.

Below you can find the abstracts of the previously mentioned speakers.

INTRODUCTION TO THE BATTERY MANUFACTURING PROCESS

Audi – Flexible Use of Laser Beam Technology for E-mobility – Jan-Philipp Weberpals, Subject Specialist Laser Beam Processes for Car Body Construction and Electromobility

The battery system of an electrically powered vehicle consists of several battery modules, which are assembled by a large number of individual battery cells. The terminals of the battery cells are interconnected by means of cell connectors. Laser welding technology is used to electrically connect the terminals to the cell connectors. This new product requirements described here, such as range, charging behavior and performance compared to requirements in car body construction, have also increased the complexity of the manufacturing methods and require the use of highly flexible manufacturing technologies. Laser beam technology offers a wide range of possible solutions for electromobility. In addition to the cell contacts as the heart of the battery module, its housing must be also connected by using laser beam technology. Thus, the challenges in prototyping are evident and the question of one equipment for different requirements is obvious. The changing materials according to the requirements also increase the possible applications of laser beam technology. In conclusion, the influence of the wavelength of the used laser source on the processing of copper materials is discussed and compared.

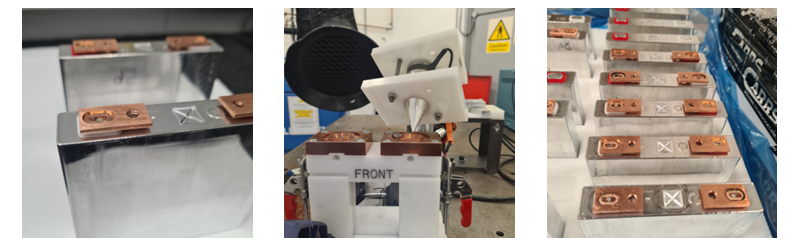

Carrs Welding Technologies – SoniLaser – Ultrasonic Assisted Laser Welding for High Volume Assembly of Automotive Battery Packs – Phil Carr, Director

Carrs, the contract welders, tackle challenging welding tasks, including the difficult task of joining copper to aluminum due to the formation of Intermetallic compounds. Their motivation is to find solutions for repairing metal components. Soni-Laser fulfilled a dream by collaborating with Brunel University to explore ultrasonic excitation for welding copper to aluminum, a critical need in the battery industry. This research aims to optimize battery connections.

SESSION 1: Photonics Applications in Cathode/Anode Manufacturing

Precitec – Photonical Quality Systems for Foil Manufacturing – Jens Reiser, Sales & Innovation E-Mobility

This presentation focuses on Precitec‘s solutions for optical sensors. In the first part, Reiser discussed the physical principles behind Precitec sensors, including chromatic confocal and interferometric measuring techniques that can achieve resolutions below 1 micron. These sensors enable the inline and contactless measurement of critical quality criteria in cell production. In the second part of the presentation, he covered topics such as (i) detecting impurities (e.g., particles in the 10 – 50 micron range), (ii) measuring thickness and edge superelevation, and (iii) inspecting cutting burrs. The presentation concluded by providing an overview of potential closed-loop strategies for future MP (manufacturing process) lines.

TRUMPF – Laser Cutting of Battery Foils – Günter Ambrosy, Industry Manager Mobility

The current rapid growth of the e-mobility sector is driving demand and innovation in the manufacture of batteries. This is particularly evident in the development of laser-based processes for the manufacture of battery cells. Whether it’s cylindrical, pouch or prismatic, all battery cells require the foils to be cut. Traditionally this has been done using mechanical processes such as slitting and stamping, but recent increases in laser powers have made lasers for cutting more appealing, to a point where they are now becoming the process of choice. Meeting industrial demands proves challenging due to the complexity of foil materials and electrode designs, making the selection of the most suitable laser technology a significant challenge. Requirements range from the slitting of thin bare metal foils to the profiling of coated materials where both bare foil and coated material need to be cut in a single process. The materials break into anodes (copper foil coated with graphite and anodes (aluminum foil coated with active Li+ containing mediums such as NMC or LFP). As ever manufacturers require the highest possible processing speeds with the highest possible edge quality which is proving challenging.

SESSION 2: Photonic Applications in Battery Cell Manufacturing

Enovasense – Laser Thickness Measurement Systems – Geoffrey Bruno, Founder

The Enovasense technology allows to measure key properties of any kind of opaque coatings on any material. The physical principle allows a fully non-contact, non-destructive and fast measurement. In the battery world, the validated applications are numerous. After electrode coating and before calendering, the surfacic weight, the density and even the level of drying of cathode and anode layers can be measured with a single-sided sensor, whatever the substrate underneath. Additionally, insulant dielectric paint thickness can also be measured on numerous parts such as the battery cell itself or heat transmission components. In the fuel cell industry, the Enovasense technology is able to measure the thickness of various types and geometries of coatings on bipolar plates, from coatings in very tiny flow fields channels to coatings that go down to nanometric levels.

SCANLAB – Next Generation Laser Scanners – Holger Schlueter, Head of Business Development

Three laser applications are identified and well understood in the field of battery manufacturing:

Cap-Can welding, Busbar to battery terminal, Battery modules. Considering the number of batteries produced, an improved cycle time is mandatory to sustain a positive business case.

Schlueter presented on-the-fly welding for 1D linear stages to improve the cycle time of these applications. Static welding mode disadvantages include undesirable laser-off times between adjacent groups of seams and additionally, by using a larger scan field, some physical aspects need to be considered for the scan field’s edges: Variation of the angle of incidence and elliptical spot geometry. Both drawbacks can be eliminated by implementing the on-the-fly capability for 1D/2D linear stages. On-the-fly mode advantages include that the pre-recording of the axis’ velocity permits to increase it until no laser-off time is identified in the process.

We showcase an application example of On-the-fly welding with linear stages. The combination of 3D-scanners, single-mode laser sources and linear stages offers a versatile setup for e-mobility applications.

Civan Lasers – Dynamic Laser Beam Welding of High-strength Aluminum Battery Enclosures – Robert Bernhard, Application Lab and Branch Manager

The progression of automotive manufacturing has precipitated a growing requirement for the welding of aluminum materials. Notably, the lightweight nature and superior thermal conductivity of aluminum render it advantageous for e-mobility applications. Nevertheless, the welding of aluminum, especially high-strength alloys, die-cast components, and the bridging of gaps, presents distinctive challenges. Conventional welding approaches fall short in concurrently addressing these issues. These challenges become particularly pronounced in scenarios such as welding battery enclosures at high feed rates and overcoming gaps between prismatic battery enclosures and their lids.

The Dynamic Beam Laser, an emerging solution within the realm of aluminum welding, offers unprecedented capabilities in the real-time shaping and adjustment of the laser beam. This technology enables the modulation of intensity distribution utilizing laser power levels of up to 28 kilowatts for welding. Such capabilities lead to precise control over the melt pool. In this presentation, Bernhard explored the novel techniques developed to overcome the challenges inherent in high-strength aluminum welding.

SESSION 3: Photonic Applications in Battery Module Manufacturing

PRIMES – Laser Beam Diagnostics in Battery Manufacturing Processes – Thomas Umschlag, General Manager

The importance of e-mobility has continuously increased over the last few years. The associated, continually increasing demand for alternative drive technologies, such as batteries or fuel cells, also places new tasks on production systems. New production concepts or requirements for existing production steps are just some of the challenges manufacturers are confronted with. Other factors that should not be underestimated such as growing competition or cost pressure in the production of batteries. Laser processes are particularly important because they have become an integral part of modern production facilities. In his presentation, Umschlag presented how laser beam diagnostics can make a significant contribution to increasing productivity and reducing costs. Options are presented for the characterization of laser-based production steps during production equipment installation, but also how system-integrated monitoring technologies can increase product quality and production excellence.

SESSION 4: Photonic Applications in Fuel Cell Manufacturing

IFSW – Institut für Strahlwerkzeuge – High-speed X-Ray Imaging of Pore and Spatter Formation during Welding of Copper Pins – Eveline Reinheimer, Research Associate

Laser beam welding is a highly efficient process for joining copper pins in electrical drives, commonly referred to as ‘hairpins.’ Pore formation can diminish the cross-sectional area, leading to increased electrical resistance and a decrease in joint tensile strength. This study compares various welding strategies to assess pore and spatter formation during Cu-hairpin welding. Welding strategies were modified by altering scan contour geometries, beam shapes, and employing adaptive line energy. Different beam shapes were achieved using a two-in-one beam delivery fiber and a Civan laser with coherent beam combining. To detect pore formation, the processing zone was monitored through X-ray imaging, while high-speed cameras were used to observe spatter formation. This approach allowed us to separately analyze the influence of scan contour and beam shape on pore and spatter formation. Ultimately, the study’s findings led to the identification of advantageous welding strategies for reducing both pore and spatter formation.

During the meeting, we had the chance to visit Motorworld, with a daily changing collection of vintage and sports car and motorbikes in the listed halls of the former state airport.

To know more about how lasers will improve e-mobility, take a look at the recording of the Online Technology Meeting on Lasers for Mobility in the Future.